Include ISO 17025 CNAS & ILAC Test Report

Item No.: 7006-22C-1

Made in China

Product description: IEC60061-3: 7006-22C-1 E27 Gauge I for Checking Side Contact Resiliency in Lampholders. According to standard IEC 60061-3.

IEC60061-3: 7006-22C-1 E27 Gauge I for Checking Side Contact Resiliency in Lampholders

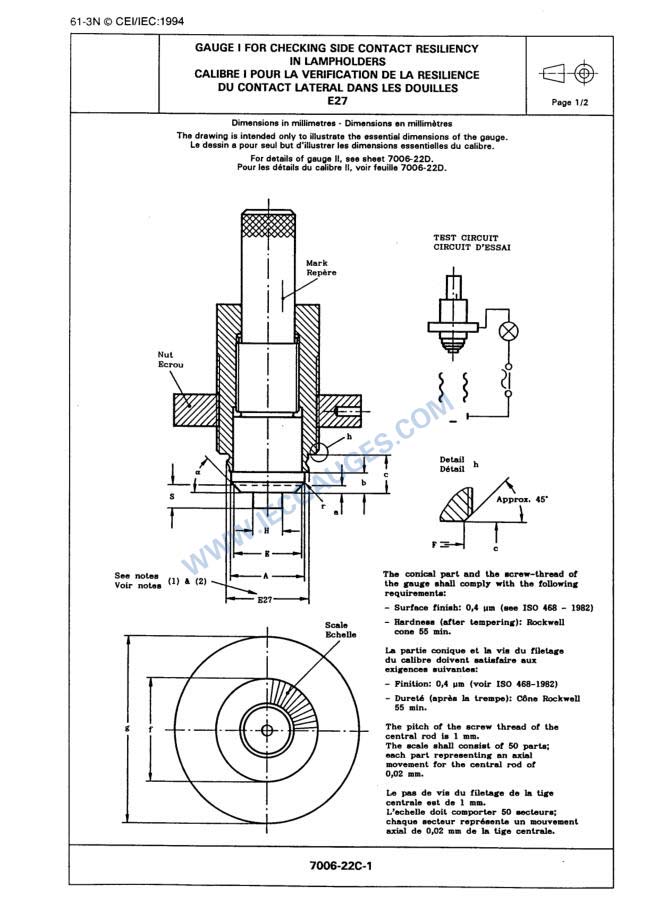

For details of gauge II, see sheet 7006-22D.

The conical part and the screw-thread of the gauge shall comply with the following requirements:

- Surface finish: 0,4 um (see ISO 468 - 1982)

- Hardness (after tempering): rockwell cone 55 min.

The pitch of the scerew thread of the central rod is 1 mm.

The scale shall consist of 50 parts;

each part repressnting an axial movement for the central rod of 0,02 mm.

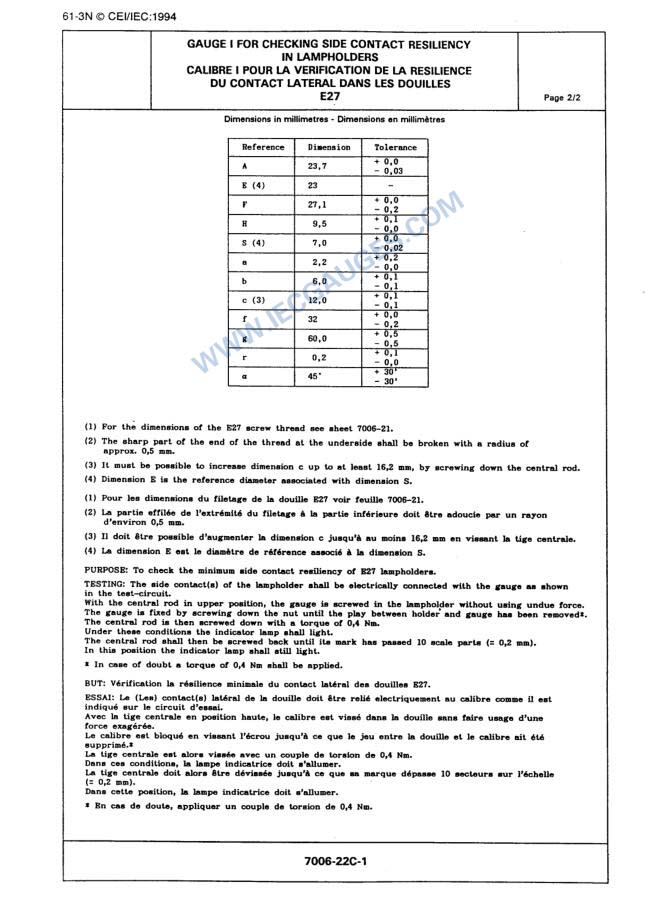

(1) For the dimensions of the E27 screw thread see sheet 7006-21.

(2) The sharp part of the end of the thread at the underaide shall be broken with a radius of approx. 0,5 mm.

(3) It must be possible to increase dimension c up to at least 16,2 mm, by screwing down the central rod.

(4) Dimension E is the reference diameter associated with dimenaion S.

PURPOSE: To check the minimum side contact resiliency of E27 lampholders.

TESTING: The side contact(s) of the lampholder shall be electrically connected with the gauge as shown in the test-circuit.

With the central rod in upper position, the gauge is screwed in the lampholder without using undue force.

The gauge in fixed by acrewing down the nut until the play between holder and gauge has been removed*.

The central rod is then screwed down with a torque of 0,4 Nm.

Under these conditions the indicator lamp shall light.

The central rod shall then be screwed back until its mark has passed 10 scale parts (= 0,2 mm).

* In case of dubt a torque of 0,4 Nm shall be applied.

Contact: Cindy

Phone: +86-13751010017

E-mail: sales@iecgauges.com

Add: 1F Junfeng Building, Gongle, Xixiang, Baoan District, Shenzhen, Guangdong, China